Anaïs Jarnoux

Recherche et développement sur la mise en forme d’un bio-matériau en algue

Recherche et développement sur la mise en forme d’un bio-matériau en algue

Details

Price & Availability

Anaïs Jarnoux

Lauréate de la récompense Dialogues du Prix Liliane Bettencourt pour l'Intelligence de la Main® 2022

Learn more

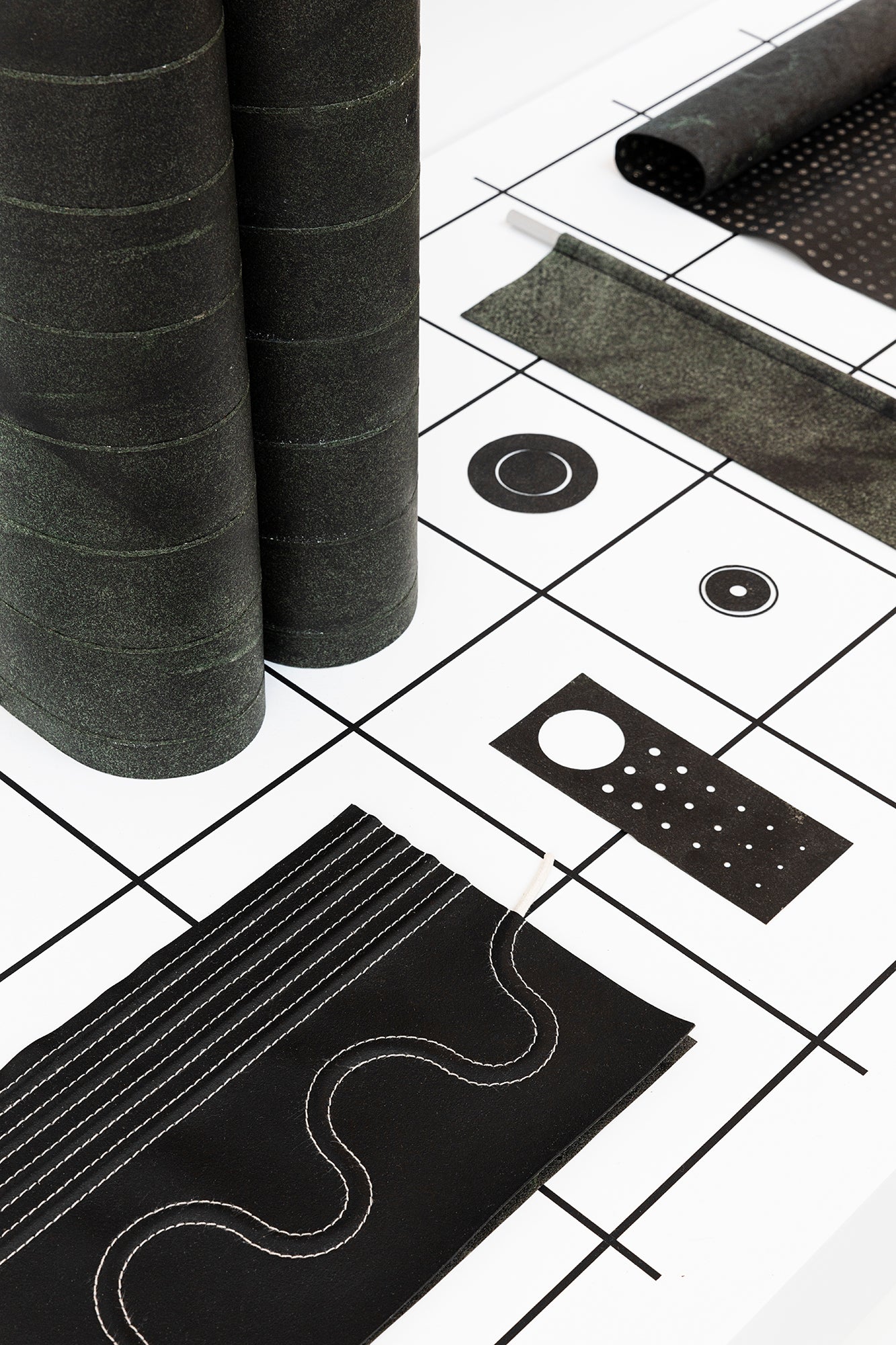

New tools and techniques specific to algae materials had to be developed. We discovered unique properties of algae that we couldn't have suspected. Assembly with water is more efficient than any glue. Algae, through their color, opalescence, surface state, and texture, offer an infinite aesthetic palette. The scraps can finally be kept, either to be melted again and recreate materials, or to be returned to nature where they will serve as fertilizer or food for insects. This project is fully part of a radical ecological approach. Everything is reusable, entirely biodegradable, and ultimately returns to the earth. This project highlights prospective scenarios that allow us to move away from mass production and integrate the ephemeral into our consumption. It tends towards a paradigm shift where solutions are drawn to reduce the impact of our anthropogenic waste.

Manufacturing process

Manufacturing process

Dimensions

Dimensions